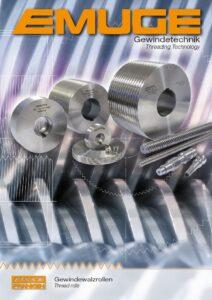

Rolling Threading

Unlike tapping or lathe threading (material removal processes), rolling threading involves creating threads through deformation. In this method, material is displaced and deformed to obtain threading on metal parts (screws, bolts, threaded rods).

This process offers several advantages:

- High dimensional and form precision

- Surface quality

- Increased static and dynamic strength of profiles

- Short machining time.

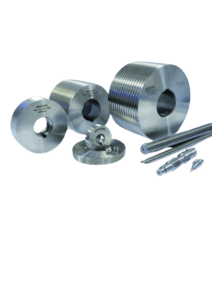

Thread rolls

Novoutils and its partner Emuge-Franken cater to your thread rolling wheel needs:

- For plunge rolling

- For through-feed rolling.

Our extensive range of thread rollis includes tools suitable for creating your profiles:

- ISO metric thread pitch, USST, Whitworth

- Trapezoidal pitch

- Oblique flank

- Wood screws and round threads

- Knurled and serrated profiles

- Vertical flank profiles